SixGunz Brewery

History

The Brewery

The Brew Pub

The Equipment

The Brewing Process

Recipes

Labels

History

I've been an avid homebrewer since 1983. Most of my brewing up until about 1996 was using malt extracts in bottled, 5 gallon batches. Since then, however, I've evolved to all-grain brewing in 10 gallon batches, using 5 gallon cornelius kegs to dispense the final product. I make a wide variety of beers, including IPAs, light (but full bodied) european lagers, amber ales, doppelbocks, brown ales, porters, and stouts. Here is a list of some of my favorites:

- Three Sheets - India Pale Ale

- Terminator "I'll be Bock" - Doppelbock

- Two Lights Porter

- Cross-Czech Pils

- Crazy Talk Pale Ale

- Black Rider Dark Lager

- Voodoo Brew - Brown Ale

- Kilt Lifter (wee heavy) - Scottish Ale

- Double-Diamond Mountain Stout

- Bite-the-Bullet Bitter

I have also put a lot of time into finishing my basements, both in Leesburg and in Colorado Springs, in order to accomodate my hobby.

Click Here to see more about the Basement Construction Projects.

The Basement Brewery

I spent the last several years finishing the basement in my new house to include a Brewery and Brew Pub. The brewing room has all my basic equipment contained in one room along with all the refridgeration required for the ten-tap system on the bar. It also has special plumbing and ventillation specifically designed for brewing.

The Brew Pub

Of course, there is not much point in brewing unless you can enjoy the resulting product in a proper setting! Since I keg all my beer, I was very excited when a friend of mine salvaged a ten-tap dispensing system from a restaraunt he was renovating. Now the challenge was to actually get ten taps operating! I mounted the taps on my bar and put new lines into the brew room where the refridgerators were located. I also added two gas manifolds to allow individual control of the CO2 pressure to each keg from the bar. I have also been working to build unique tap handles representative of the beers I make.

As you will see if you visit the Motorcycle Touring side of my website, I also like to collect Logo Pint Glasses from all the Breweries/Brewpubs I visit on my travels across the country. Here is a picture of the approximately 180 individual and unique glasses I've personally collected on my trips.

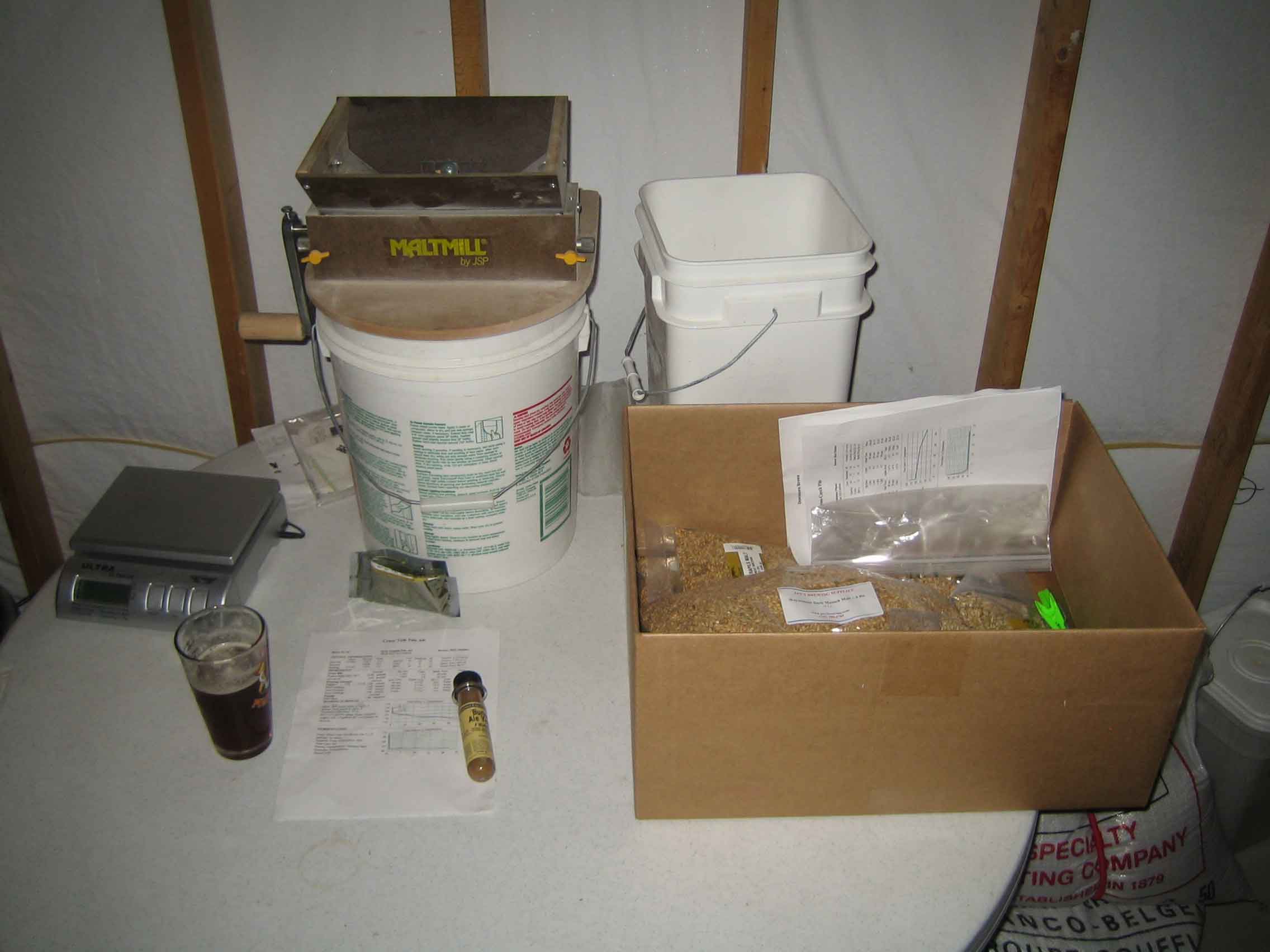

The Equipment

As an engineer who rarely gets to do engineering anymore, I have gone a little overboard in designing and building my brewing equipment. I have converted several large kegs into a sparge water tank, mash tun, boiling pot, and fermenters. A friend and I also welded together a very handy brewing stand I designed, complete with two propane burners, a movable platform for lifting the sparge water tank, and a heat exchanger. More recently, I've also built in a pump, an in-line oxygenator, and a manifold for easy re-configuration of the liquid flow.

The Brewing Process

All-grain brewing begins with the process of "Mashing", or steeping the cracked,

malted, grains in water between 149 and 158 deg. F for 60-90 minutes. This

converts the starches in the grain into fermentable sugar. The sugar-water, or

"Wort" is then

"Sparged", or rinsed from the grain husks by slowly drawing the liquid out of the mash

tun while sprinkling hot (170 deg F) water on the top to rinse all of the sugars

out.

All-grain brewing begins with the process of "Mashing", or steeping the cracked,

malted, grains in water between 149 and 158 deg. F for 60-90 minutes. This

converts the starches in the grain into fermentable sugar. The sugar-water, or

"Wort" is then

"Sparged", or rinsed from the grain husks by slowly drawing the liquid out of the mash

tun while sprinkling hot (170 deg F) water on the top to rinse all of the sugars

out. The wort is then boiled with hops for at least 60 minutes. Hops added for the entire boil provides bitterness, hops boiled for 20-40 minutes adds flavor, and hops added during the last couple of minutes of the boil adds aroma. Each recipe will call for different types of hops to be added at different times to give the beer is character. Once the boil is complete, the wort is pumped through a heat exchanger (and an in-line aeration unit) to cool it to below 75 deg F and into the primary fermenter where the yeast is added.

The beer is then allowed to ferment for several weeks, which is the process of the yeast consuming the sugars in the wort and converting them to alcohol and carbon dioxide. Once fermentation is complete, the beer is filtered (optional - and only if using kegs) and kegged. Carbon dioxide is then added to the keg to carbonate. If bottling, DO NOT filter the beer. Instead, add a small amount of priming sugar and bottle - additional fermentation will take place and naturally carbonate the beer in the bottle.

Recipes

Terminator "I'll be Bock" - Doppelbock

12 Gal. OG: 1.061, FG: 1.020, 29 IBU's, 20 SRM

Alcohol: 5.4% (v/v),

Ingredients:

Grains:

Klages 16 pounds

Munich (Dark) 10 pounds

Vienna 4 pounds

Crystal 90 1 pounds

Chocolate 0.5 pounds

Hops:

Hallertauer leaf, 4 ounces, 4.5 % Alpha Acid (60 min)

Yeast:

Wyeast #2206 Bavarian Lager

Directions:

Mash grains in 9 gallons of water at 156 deg. F for 90 minutes. Sparge with 10 Gallons water at 170 deg. F. Boil for 60 min with 4 oz Hallertauer. Ferment at 50 deg. for 6 weeks.

Cross-Czech Pils

10 Gal. OG: 1.060, FG: 1.017, 27 IBU's, 6 SRM

Alcohol: 5.7% (v/v),

Ingredients:

Grains:

Belgian Pils 16 pounds

Cara Pils 2 pounds

Munich 2 pounds

Wheat 1 pounds

Hops:

Saaz leaf, 5 ounces, 2.2 % Alpha Acid (90 min)

Saaz leaf, 1 ounces, 2.2 % Alpha Acid (30 min)

Saaz leaf, 2 ounces, 2.2 % Alpha Acid (50 min)

Yeast:

Wyeast #2278 Czech Pils Lager

Directions:

Mash grains in 5.5 gallons of water at 140 deg. F for 30 minutes. Raise temp to 155 for 90 minutes more. Sparge with 8.5 Gallons water at 170 deg. F. Boil for 90 min using above hops schedule. Ferment at 48 deg. for 3 weeks, then at 40 deg. for 6 more weeks.

Here are a few Labels in development for upcoming Brews:

Contact me at: rf6gunz@yahoo.com

Copyright © 2007, Rick Fletcher